Certified quality management (ISO 9001:2015)

Flawless casting for your contentment

Hugo Lahme GmbH is today one of the leading foundries in the area of red brass and bronze alloys due to many years of experience and the existing know-how as well as our very high vertical range of manufacture. Customer satisfaction plays a crucial role for us. The extraordinary quality standards of Hugo Lahme GmbH are present in every production process. All castings pass through an individual quality inspection before shipment. Qur quality assurance ensures that you receive flawless castings.

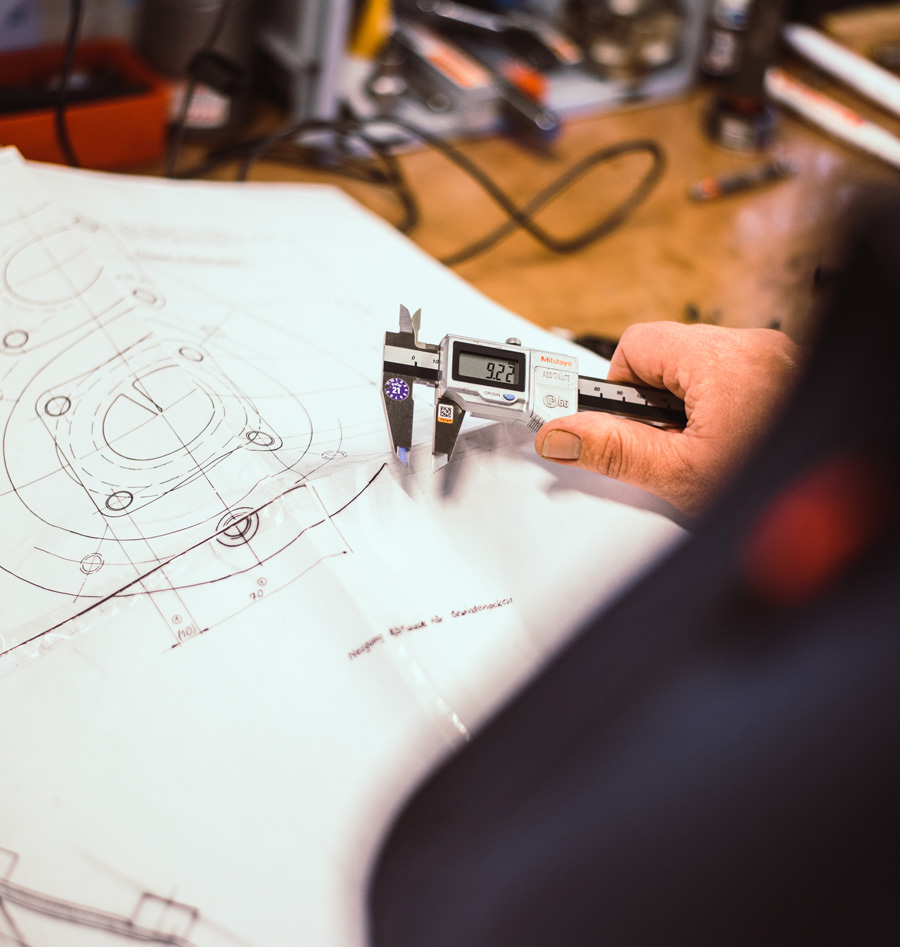

In-process quality control and the highest possible level of care

Preventive quality assurance measures and in-process inspections are the key to our high product and process quality. All of our excellently trained employees ensure the highest level of quality with the greatest possible care and continuous monitoring at all levels. What this means for our customers: Guaranteed quality at a high level for all services provided in our company.

Certified quality management

Our quality management system is certified in accordance with ISO 9001:2015. Our qualified employees ensure the quality of our products starting with the incoming goods control, the inspections during production and the final inspection. Our processes are described in an electronic, interactive management system and are continuously optimized.\nFurther improvement of product quality is achieved by continuous refinement of the production technology and the level of mechanical equipment.

Various test methods

Various destructive as well as non-destructive tests can be applied for product qualification. The following test methods are available:

- Spectral analysis with a radio spectrometer (SpectroMaxx)

- 3D coordinate measuring machine (Wenzel)

- 3D measuring arm (Hexagon)

- Leak test (air under water and differential pressure method)

- Endoscopy (Olympus)

- Roughness measuring machine (Jenoptik)

- Tensile and hardness testing by accredited laboratory