Coldbox cores and croning cores

Cores for complex shapes and geometries

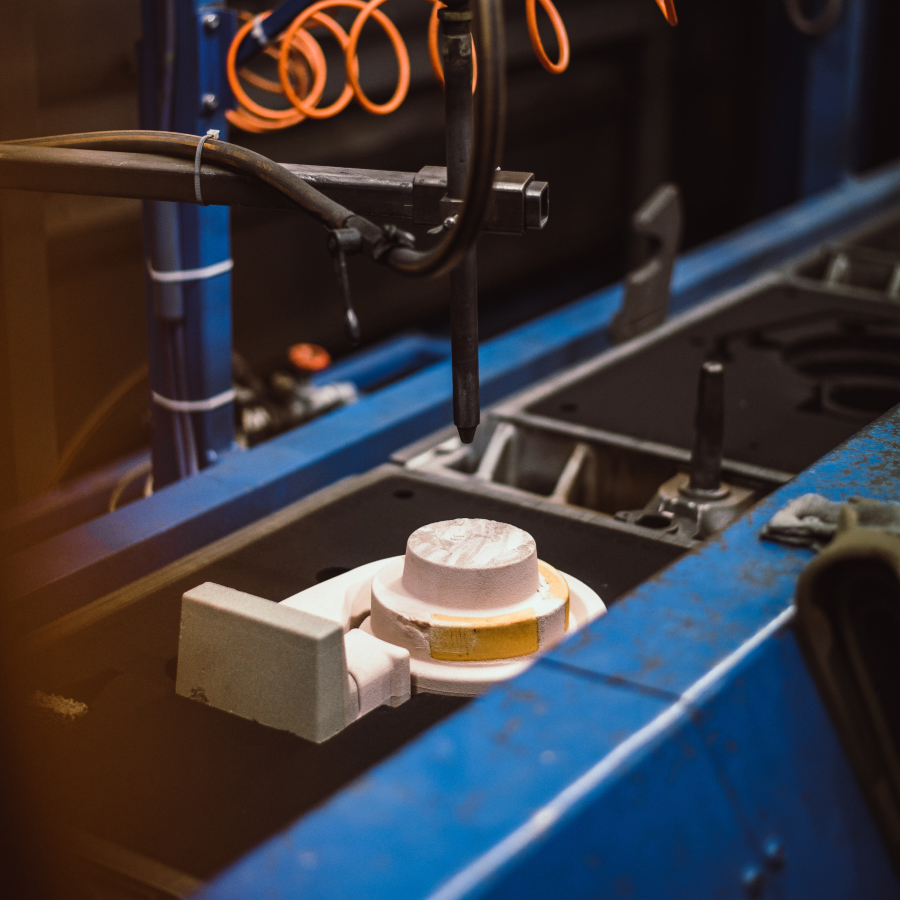

We offer the production of your cold box cores and croning cores as an additional service for you. Castings can have complex shapes, which means that a cavity inside can only be produced with sand cores. The core production of these cores is usually one of the first steps in the production chain of a foundry. Here, the cores are formed from compressed sand.

Wide range of experience in handling cores

The cores are placed in the molding box and provide the desired cavity in the subsequent casting. Dealing with cores in construction requires a high level of experience. Cores are always of decisive importance for the quality and functionality of a casting. We have been expanding this experience in core production on a daily basis since 1945.

State-of-the-art machinery for your cores

We produce your cold box cores with state-of-the-art machines. With excellent strength values and very good dimensional accuracy, cold box cores meet the growing requirements for modern castings. We also produce croning cores for you with an equally high standard.

Core box size of 600 x 800 x 700 mm

We manufacture your cores in various sizes with a maximum core box size of 600 x 800 x 700mm. We produce your cores from quartz and special sands on high-performance core shooting machines. We transport and pack your cores in for example lattice boxes and ship them controlled and ready for use directly to you. Please contact us for a non-binding offer for core production.