Reduce reject rates. Increase productivity.

Significantly reduce rejects and increase productivity

Leaks that sometimes occur can be reworked with our vacuum impregnation system using the Maldaner process - we are also happy to do contract impregnation. This process can significantly reduce rejects, increase productivity and considerably improve the ecological footprint. Vacuum impregnation is a gentle method for sealing leaks that can occur in casting process.

Through vacuum and impregnation resin to leak-proof castings

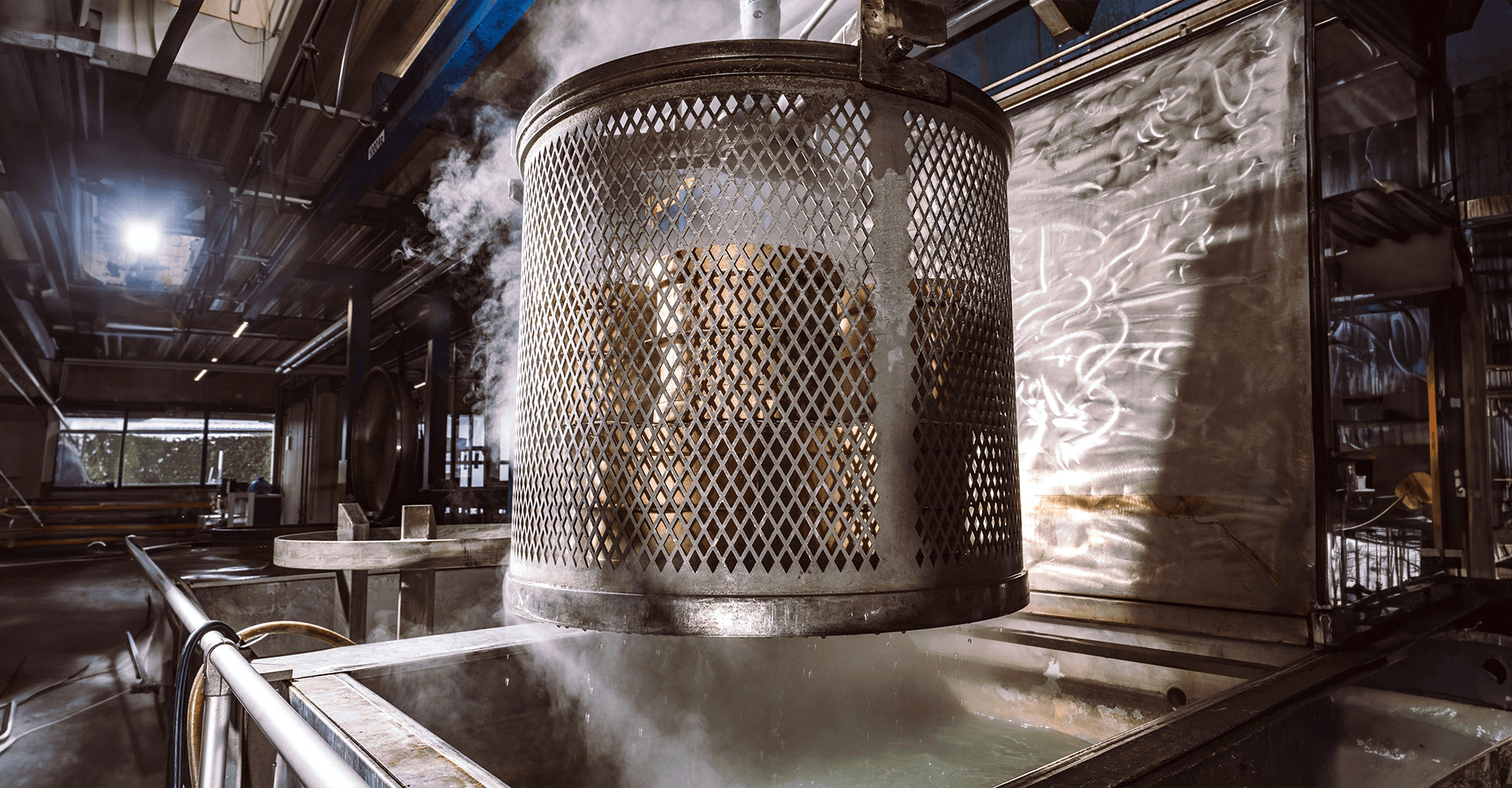

For the vacuum impregnation process, the castings must be free of grease and be deeply dry. The air will be evacuated from the porous areas by a vacuum of less than 10 mbar. The impregnating resin then permeates into the pores. The removal of the vacuum allows the impregnating resin to permeate deeply into the pores of the castings and reach even the finest porosity. The parts are then washed off in a water bath so that no surface film remains. The impregnating resin is then cured in a polymerization bath at 90°C. Curing prevents of bleeding out the acrylic resin in the pores.

No change in the functional characteristics of the casting

The vacuum impregnation process enables you as a manufacturer to use castings that would otherwise have to be scrapped. Vacuum impregnation helps and seals the open porosity of the casting without changing the functional characteristics of the casting. We also offer vacuum impregnation of leaky castings as an additional service as a contract impregnation. Reduce significant costs and get a time advantage in the production of your articles. Contact us for a non-binding offer for metal casting impregnation.