Machining with the state-of-the-art machines

Contract manufacturing also with complex geometries or tolerances

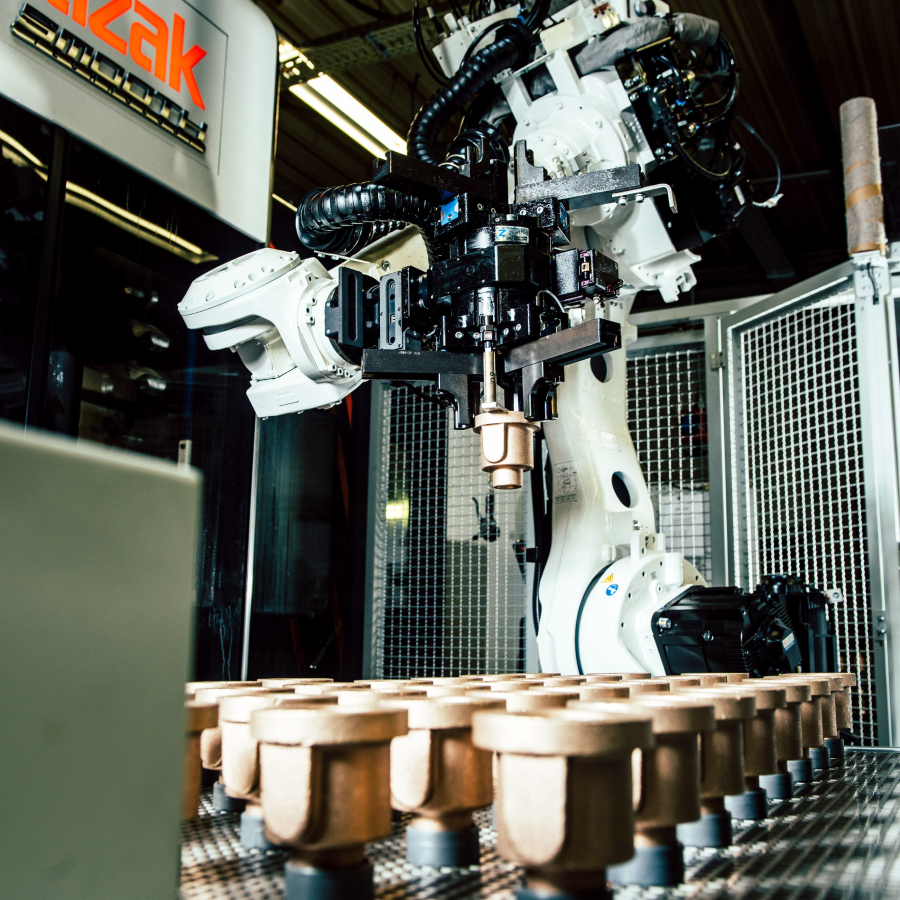

As a full-service partner, we provide the mechanical finishing of your components as a service. Our foundry in Ennepetal is linked to an state-of-the-art mechanical processing facility. Our aim is to be able to machine any of your castings produced by ourselves. We do the contract manufacturing also for complex geometries or tolerances as a service for you. Precision and efficiency are our top priorities in manufacturing.

State-of-the-art processing for your own benefit

Continuous investing in our employees and machines enables us to economically mechanically process your castings directly at our site in Ennepetal. In our production, all necessary mechanical processing such as milling, turning, drilling or sawing are carried out according to customer drawings. For this purpose, we have an extensive machine park of state-of-the-art CNC machining centers.

High flexibility and customization in processing

By equipping the machines with different tools it is possible for us to carry out one work step of contract manufacturing directly after the other. This allows us to keep tooling time low. Your castings are manufactured and machined in an individual way by modern mechanical processing. This gives us a high degree of flexibility to respond to your contract manufacturing requirements in real time.

Wide range of machines for milling, turning, drilling or sawing

In order to meet your requirements, significant resources have been invested in modern CNC machines and employee training. Our mechanical machining in production is currently done with these machines:

- 1 DMG machining center

- 3 MAZAK machining centers

- 3 MAZAK turning/milling centers

- 7 MAZAK lathes

- Various special machines